Solutions

Seals

Seals

At Fluorocarbon we are dedicated to the manufacture of high performance sealing solutions and bearings to suit your specific needs.

Seals can be provided in a range of PTFE and high performance polymer materials, specified to meet and exceed the demands of the application.

We offer custom solutions for use throughout many industries including chemical, pharmaceutical, food processing, aerospace, automotive and offshore.

Manufactured for use in the most demanding conditions our seals offer the following benefits:

- Excellent chemical resistance

- Wide operating temperature range

- Very low coefficient of friction

- No stick/slip effect

- High resistance to wear

- Good dry running properties

Whether a standard seal or a custom requirement, our dedicated technical team can provide you with innovative and effective solutions to your needs.

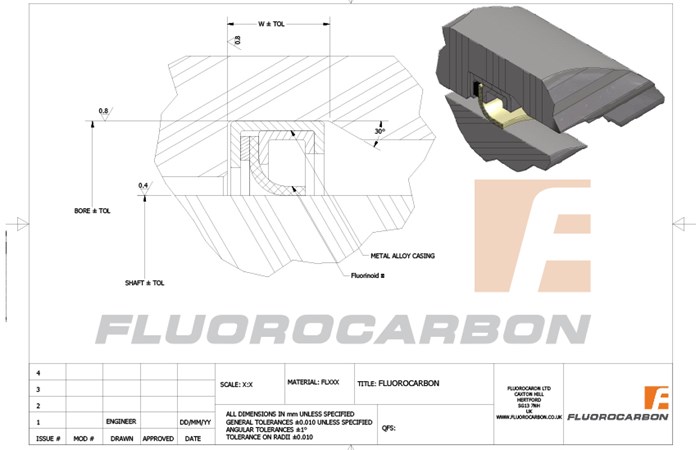

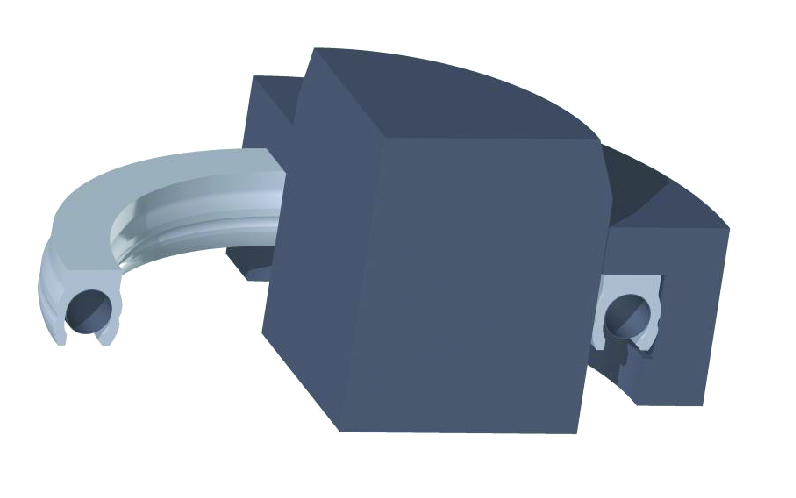

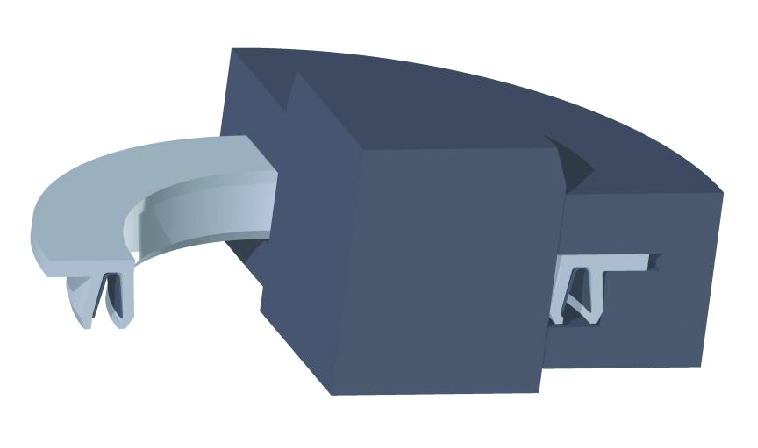

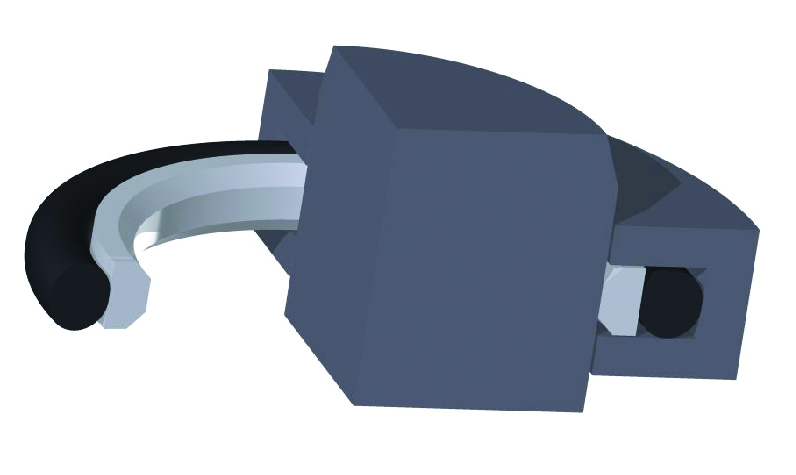

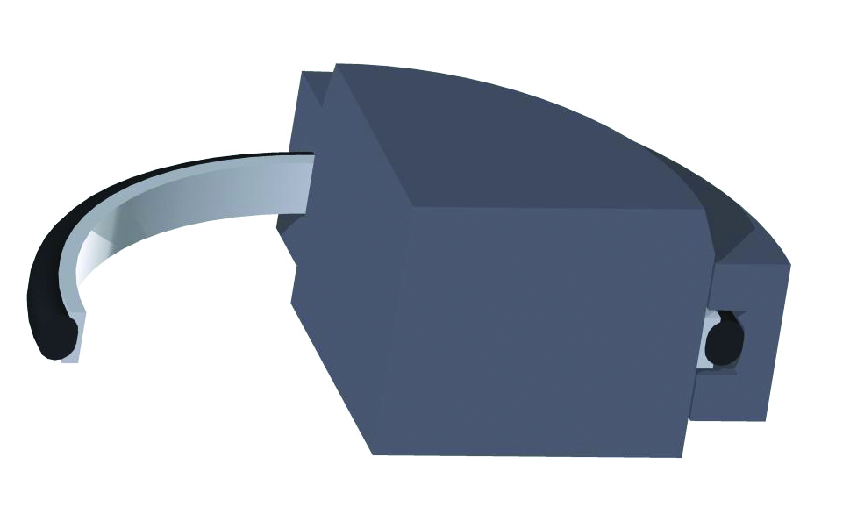

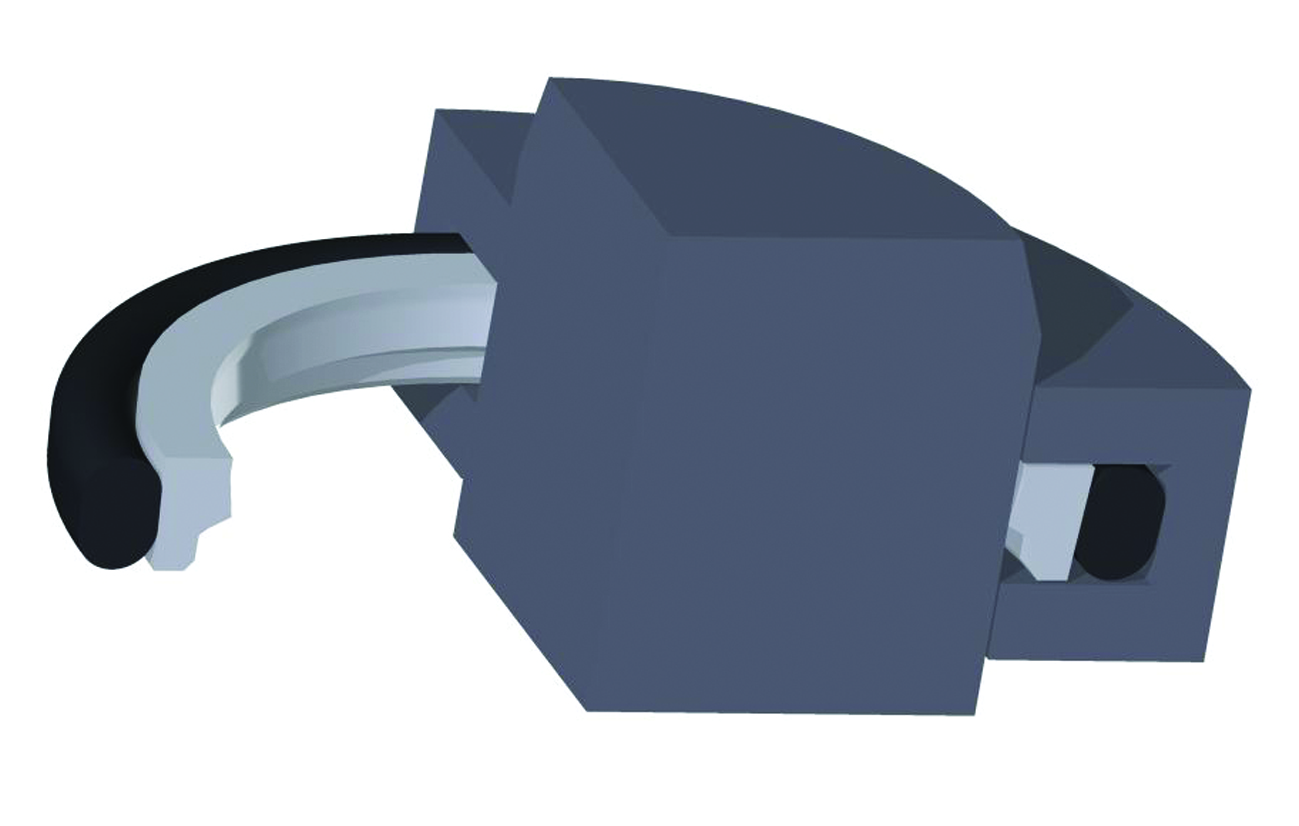

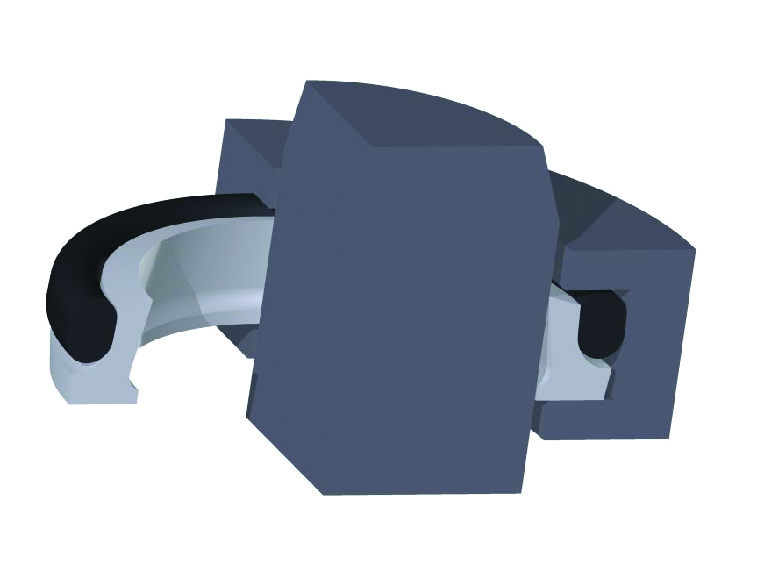

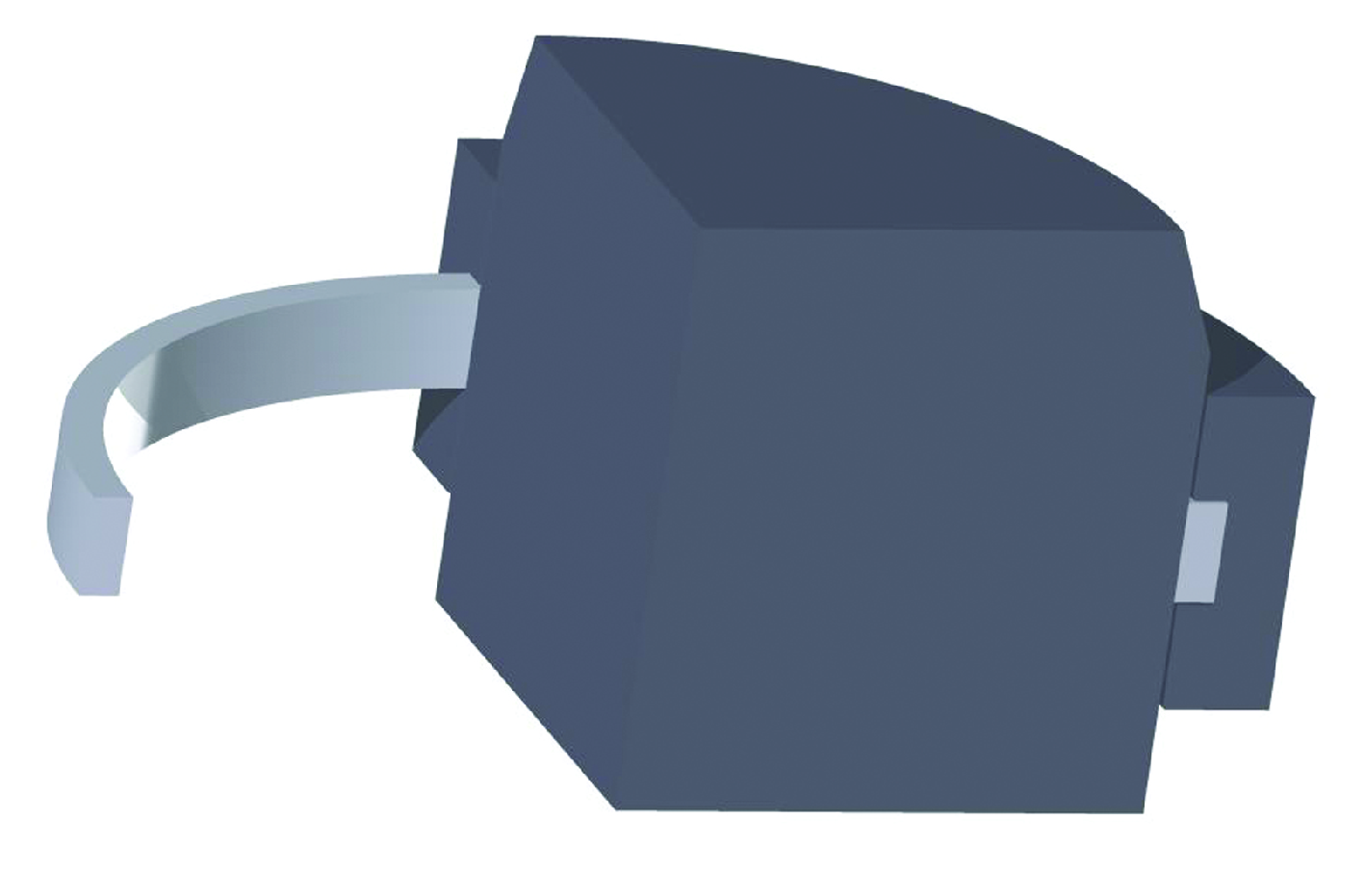

Rotary Shaft Seals

As part of our seal range Fluorocarbon can provide Rotary Shaft Seals that utilize our wide range of PTFE materials. A typical Rotary Shaft Seal sits between a rotating shaft and a fixed housing. The outer surface of the seal is fixed to the housing, while the inner lip of the seal is pressing against the rotating shaft.

The seal housings are usually metallic and can be specified to meet customer requirements. The sealing lip or lips can be specified with directional hydrodynamic features to improve sealing. Where sealing at lower pressure becomes an issue, the lip can also be spring energized.

PTFE Radial Shaft Seals are usually made of a metal insert and a special grade of filled PTFE, occasionally using a spring-energized sealing lip.

Fluorocarbon have various grades of PTFE filled materials depending on the application. Our standard Rotary Shaft Seals are used to provide sealing and wiping functionality for rotating movements, to very high speeds, a large temperature range (-196 to 260C) at reasonable pressures.

Other benefits of PTFE:

- Low friction

- Resistance to wear and tear

- Chemicals compatibility

- Performs extremely well with most fluids and gas

- Good in dry running applications.

Rotary Shaft Seal housings can be supplied in various materials to match the application.

Advantages of PTFE Rotary Shaft Seals:

- Modern lip design provides low radial forces, including hydrodynamic seal elements.

- High resistance to chemicals and petroleum-based fuels including petrol, diesel and LPG.

- Excellent chemical resistance

- Wide operating temperature range

- Very low coefficient of friction (low torque)

- No stick/slip effect

- High resistance to wear

- Dry run capability (PTFE)

- Very high shaft surface speeds

- Sealing large eccentricities

- Good static sealing

- By directional sealing keeps media separated on a single shaft.

Applications for Rotary Shaft seals:

- Food and Chemical Industries

- Semiconductor

- Aerospace applications

- Construction equipment

- Agriculture machines

- Heavy off-highway - gearboxes, axles motors.

- Motor sport

- Renewables Energy

- MOD

- Mining

- Compressors

- Oil & Gas

Service

- Available in hydrodynamic, plain and multi-lip configurations

- A wide range of materials to suit the demands of the application.

- Low volume requirements can be constructed from machined shells so there are no tooling charges.

- High volumes can be manufactured from pressed shells reducing unit costs.

Bespoke Designed Seals

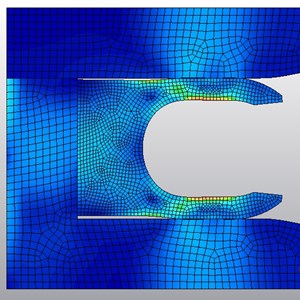

Fluorocarbon’s team of engineers can specify a range of sealing and bearing components to meet the demands of a variety of applications.

With a wide selection of materials and configurations already in our range of products, we have produced seals and bearings to seal at extremes of pressure over 2000 Bar (30,000 psi), velocities over 15m/s and temperatures from a few Kelvin to over 700°C (1200°F).

Our understanding of many applications has allowed us to work with our customer’s application engineers in recommending the best solution for their problems.

Such examples include:

- Seal bellows manufactured to cope with large extension, without detriment to life expectations.

- Fluoropolymer over-moulded bearings in water pumps

- Unique double sealing configuration for valve seats.

- Low wear materials for seals and bearings in Rotary Dryers

- Material specifically produced for dynamic, cryogenic seals.

- Large diameter fabricated seals

We welcome your enquiries for seals, bearings and related components

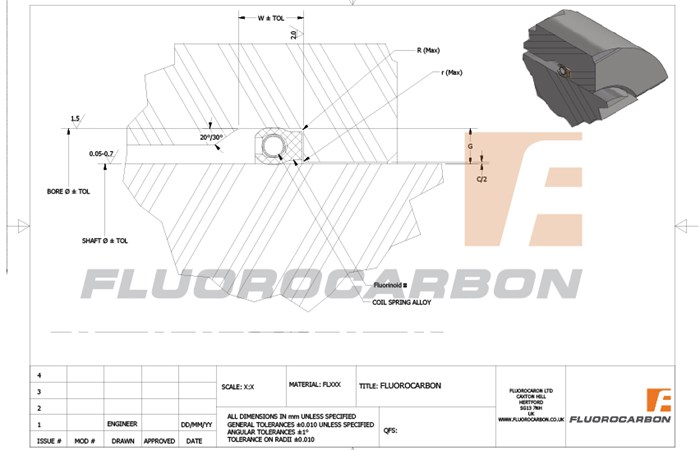

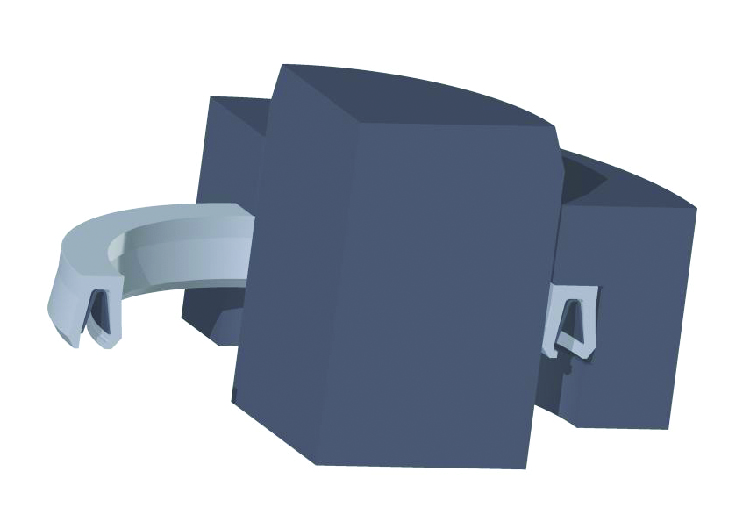

Spring Energised Seals

Whilst PTFE offers many advantages in sealing applications, it typically requires an energiser to maintain and enhance sealing forces.

Our range of spring energised seals incorporate a metallic energiser of either a ˜V’ or coil section. The varieties of spring offer light and heavy loading to ensure the most effective sealing performance across a wide range of pressures for static and dynamic applications.

Typically single acting, the seals also allow pressure energisation to further enhance the seal performance.

- Capable of up to 600 Bar (8700 psi)

- Service temperatures from -196°C to 260°C

- Diameters up to 3.0m (118")

- Available in arrange of configurations for internal, external and Flange applications

Spring energised seals are available in a range of materials of Jacket and Spring to suit the application, with many grades of spring such as Elgiloy® and Stainless Steel available from stock

F500 is a single acting seal for pneumatic and hydraulic applications, and is designed to fit ISO groove sizes. It can be used in slow rotary applications

F600 is a double lip, single acting seal for pneumatic and hydraulic applications, and is ideally suited to high pressure slow dynamic applications

F610 is a single lip, single acting seal for pneumatic and hydraulic applications, and is ideally suited to high pressure slow dynamic applications.

F700 is a single acting seal for rotary applications. The flange prevents seal rotation. This design is suited to low PV applications where space is limited

Elastomeric Energised Seals

Whilst PTFE offers many advantages in sealing applications, it typically requires an energiser to maintain and enhance sealing forces.

Our range of elastomeric energised seals incorporate O rings or square section rings in a selection of materials as required by the application. All elastomeric seals are available in piston or rod sealing configuration.

- Capable of up to 340 Bar (5000 psi)

- Speeds up to 15m/s

- Will stretch to fit closed grooves

- Diameters up to 1.5m (59")

F100 is a double acting seal forpneumatic and hydraulic applications, and is designed to fit specific groove sizes.

F200 is a double acting seal for pneumatic and hydraulic applications, and is designed to fit in standard 'o’ rings grooves.

F300 is a single acting, low friction seal for pneumatic and hydraulic applications.

F400 is a wiper ring designed to prevent the ingress of dirt and moisture into pneumatic and hydraulic systems. They are usually used to compliment other seal configurations.

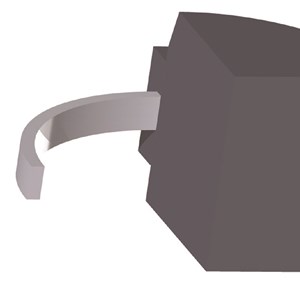

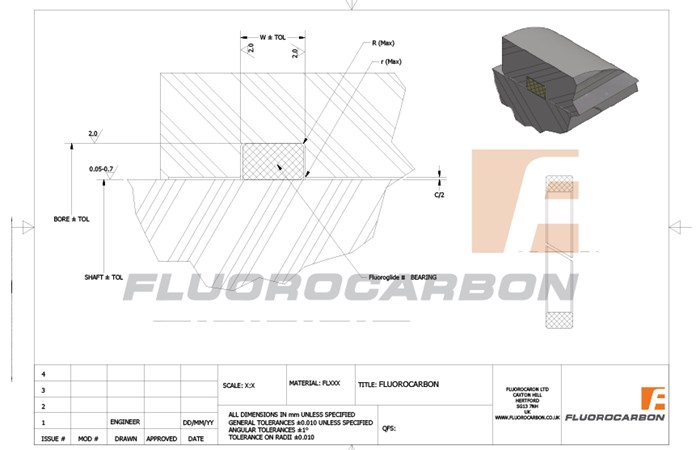

Fluoroglide® Bearings

Fluoroglide® PTFE bearing strips are used to guide pistons and piston rods in hydraulic and pneumatic cylinders to prevent metal-to-metal contact. Seal life is considerably improved when bearing strips are installed adjacent to PTFE piston and rod seals by ensuring concentricity and damping vibrations.

F800 Fluoroglide® bearings are available to fit the standard groove sizes detailed and can be manufactured to suit almost any application.

Fluoroglide bearings can supplied as strips with end configurations to suit the reciprocating or rotary application, or in roll lengths for the customer to cut to suit.

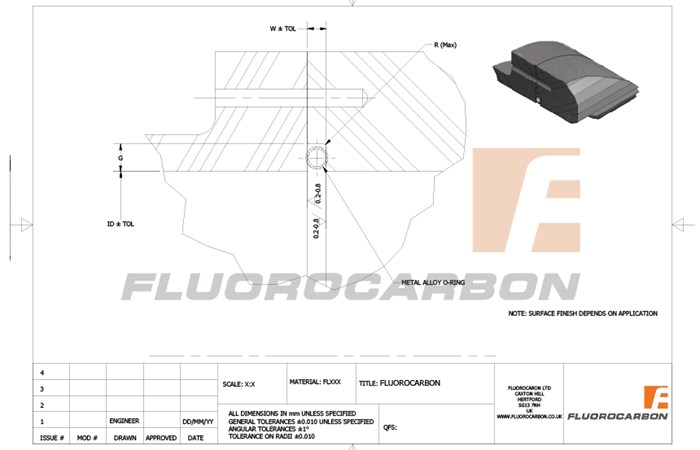

Metal Sealing Rings

Metal O and C rings are used as a deformable seal in a static sealing situation. The ring is located between two flanges or similar and undergoes a controlled compression. They are defined by their free height which is the cross section in the axial direction of the seal. The free height of the seal is compressed down to the groove depth.

- Temperature range from cryogenic to 850°C

- Pressure range from ultra high vacuum to 1,000 MPa

- Compatible with a large range of media

- Corrosion resistant and radiation tolerant

- Simple and reliable sealing

- No 'out gassing'

- Wide range of sizes up to 2.3m (90")

- Available in non-circular configurations

The resistance of the ring to compression enables it to form an effective seal when compressed. The resilient effect of the seal is increased by pressurising the internal volume of the ring and is known as gas filled.

If the system to be sealed is a very high pressure - this can be used to provide additional sealing effect. System actuation is achieved by allowing the high pressure to enter the seal through either vent holes in an O ring, or through the open slot of a C ring.

Metal O ring seals have a certain degree of elasticity. This is known as springback. The springback is the elastic part of the seal deflection when it is installed in a groove.

This influences the seal’s ability to absorb or compensate for hardware variations due to temperature loadings, and thus maintain the seal integrity.

Metal C rings obtain this springback with a spring energiser further maintaining the seals integrity in applications and hardware variations as above.

A softer plating or coating material can be applied to Metal O and C rings to maximize sealing performance in difficult applications. The soft coating material yields during the ring compression and fills any surface machining marks. Most common plating and coating is Silver or PTFE.

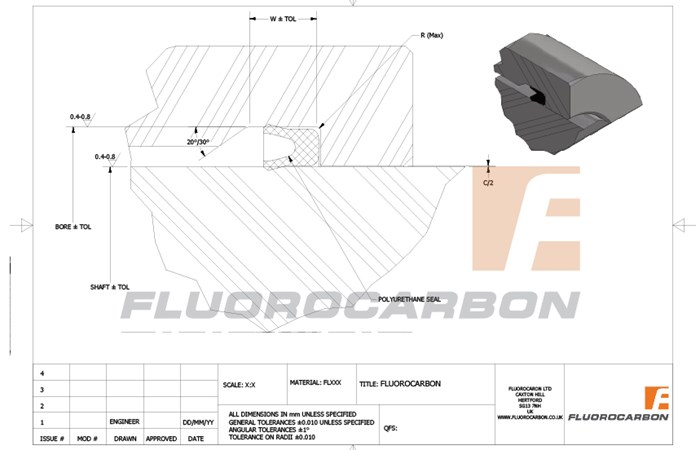

Polyurethane Seals

Our range of polyurethane seals has been manufactured for both hydraulic and pneumatic use, all to fit within the ISO standard groove dimensions.

- Capable of up to 700 Bar (10,000 psi) depending on design

- Temperatures between -40°C to 85°C (-40°F to 185°F)

- Available in various hardness and grades

- Diameters up to 2.5m (98")

When used in hydraulic applications, either internally, externally or as U-seals, our range offers many added advantages over rubber and/or fabric reinforced.

Polyurethane seals and components offer many benefits making them ideal for the glass and metal forming industries.

Benefits Fluorocarbon Polyurethane Seals

- Non-marking

- Extended life

- Stable elasticity

- Resistance to splitting

Service

- Approval by the US Food and Drug Administration makes our seals and components ideal for food filling machines.

- Our seals are manufactured with interference already built into the sealing lips, allowing low pressure start up.

- The seals are suitable for subsea use, with materials having been approved for sea water, slurry and gases.

- Many seals and wipers in polyurethane can be offered up to 2.5 metres in diameter, suited for use in hydraulic presses.

- All our polyurethane grades have excellent hydrolysis resistance.

- We can add a number of additives to improve specific properties, such as resistance to fire, mould, mildew and fungus. In dynamic applications the inclusion of MoS2 will help to reduce friction.