Why use Rotary Shaft Seals in Wind Energy Applications

March 2022

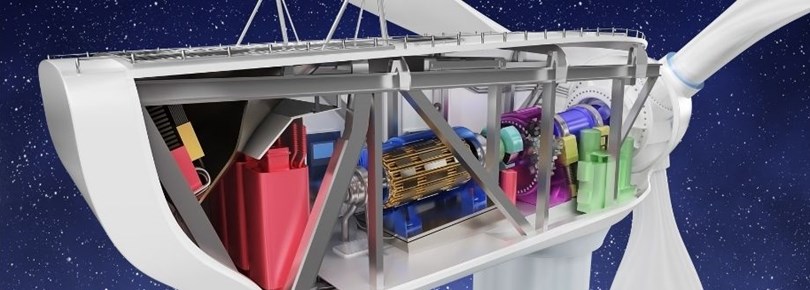

The Wind Energy Industry continues to find new ways to increase the lifetime and reliability of wind turbines.

As wind energy moves to larger, lighter-weight turbines located in harsh and remote locations, service life and reliability have grown increasingly more important.

Engineers rely on excellent sealing solutions so that there is no need for maintenance too frequently, after all, machines are only as good as their parts are and sometimes even the smallest of components tend to have the largest influence on the lifespan and reliability of the entire system.

Whether onshore or offshore, wind turbines need to withstand large-scale temperature changes. As a result, sealing components need to be made with materials that can withstand these extreme fluctuations, especially extreme cold, without comprising shape, structure, or sealing ability. This makes the choice of material a critical component in the development of a proper sealing system.

One of the best materials for wind energy seal applications, both onshore and offshore, is PTFE.

-

PTFE is a tough, flexible, non-resilient material of average tensile strength but with great thermal properties and excellent resistance to chemicals.

-

The coefficient of friction is unusually low and believed to be lower than any other solids.

-

PTFE is an outstanding insulator over a wide range of temperatures and frequencies. The volume resistivity is above 1018 Ω.cm with power factor very negligible over a huge range of temperatures.

-

PTFE has a low coefficient of thermal expansion compared to many other polymers which means it changes geometry very little when temperature changes occur.

-

PTFE also has an extensive operating temperature range of -165°C and 260°C with a melting point of 320°C. This allows it to maintain performance at the high speeds involved with wind turbines as well as the extreme temperatures involved with their operating environment.

PTFE Rotary shaft seals have become essential to the functionality of wind turbines; however, the operating environment has its challenges:

-

One of the challenges that a PTFE rotary shaft seal must deal with in this environment is the incredibly high speed of the propellers. Extremely high speeds mean that friction between the shaft and the seals will generate heat, which means energy loss. These high speeds also lead to faster wear. Low friction and excellent wear resistance are one of the most important features that PTFE can offer.

-

Another challenge faced by the PTFE rotary shaft seals are also extreme temperature changes. Temperatures can drop to cryogenic levels that’s why the material must be dimensionally stable despite these temperature changes and maintain exceptional performance. Temperatures can also impact the type of lubricant that can be used with the seal. As PTFE seals are self-lubricating, making them maintenance-free. In the wind power industry, this is extremely important for keeping the turbines running without issues.

-

The exposure to salt water, UV and weather events face an extra set of challenges that can cause rapid degradation of certain materials. Exposure to moisture can also cause problems for wind turbine seals. Some materials will absorb water which will deform their shape.

Fluorocarbon provides a range of highly effective and easily maintained sealing solutions for wind turbines that can prolong service life.

To find out how we can support your projects contact info@fluorocarbon.co.uk