Extrusion Gaps and Anti Extrusion Rings

November 2017

Extrusion Gaps and Anti Extrusion Rings

At Fluorocarbon we are dedicated to the specification and manufacture of high-performance seals and bearings to suit your application requirements. Seals can be provided in PTFE and filled PTFE materials designed to give enhanced performance.

When sealing at elevated temperatures and pressures, the amount of clearance between the opposing piston and housing, behind the seal, becomes critical. This clearance is termed the extrusion gap.

High pressure, particularly in combination with elevated temperature, can cause the seal to extrude into the clearance and cause premature failure. Extrusion gaps should always be kept to a reasonable minimum, and should not exceed the recommended values.

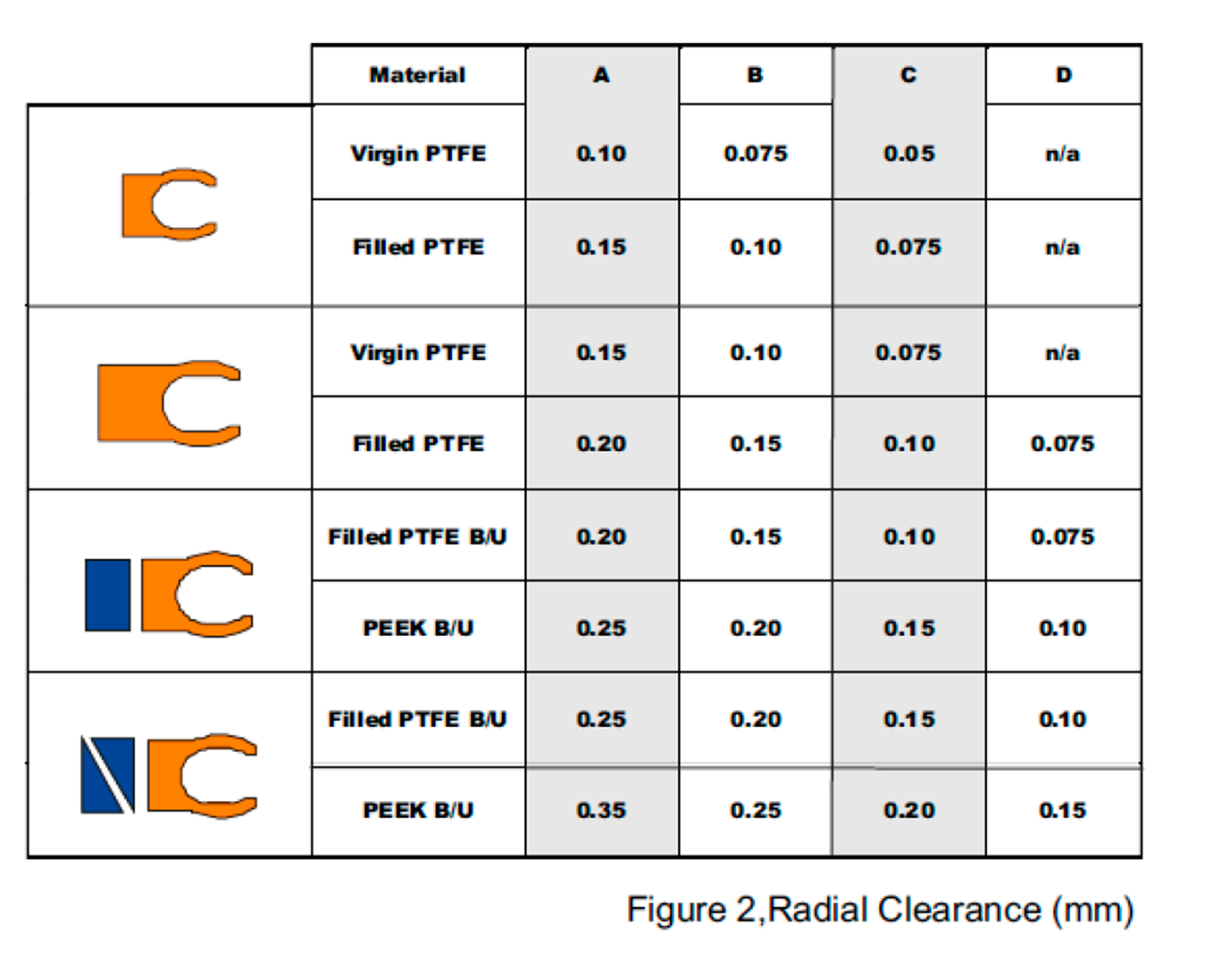

By modifying the heel of the seal or incorporating anti-extrusion rings, as shown, larger extrusion gaps are acceptable.

The anti-extrusion ring is generally of a material with a higher flexural modulus like PEEK but can also be supplied in metals if required.

The seal can also be supplied with a profiled angled heel and a single angled anti-extrusion ring. This allows the anti-extrusion ring to float radially within the housing. This is particularly useful in applications where the applied pressure causes a swelling of the housing and is largely evident in large diameter welded valves and connectors.

To find out how we can support your projects contact info@fluorocarbon.co.uk