What makes plastic high performance?

March 2017

What makes plastic high performance?

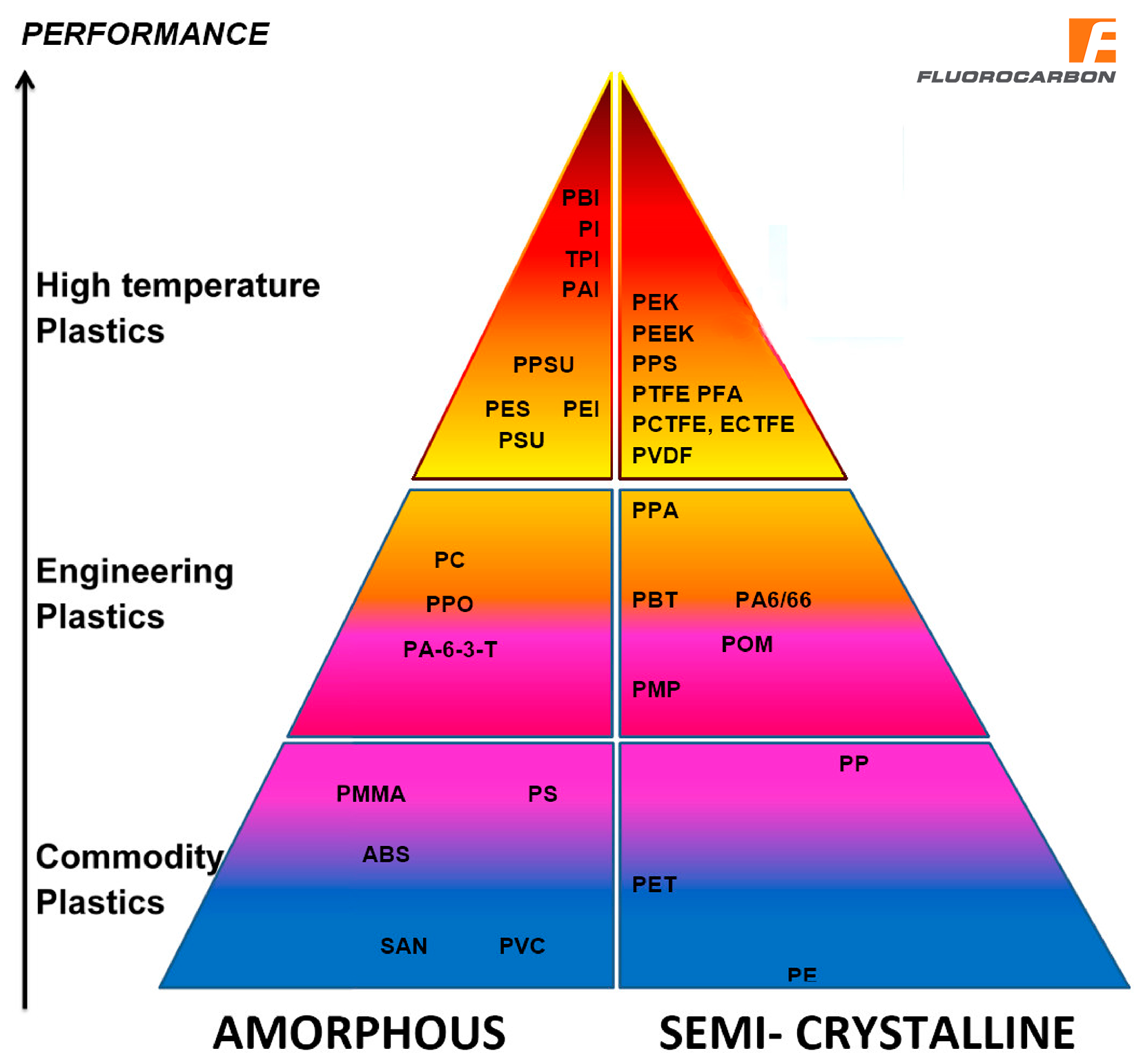

High-Performance Plastic, High-Temperature Plastic, High-Performance Thermoplastic, High-Performance Polymer…However you refer to this range of materials, what makes them different to other types of plastic?

They are distinguished primarily by their temperature stability, but also their mechanical properties.

Often chosen for applications requiring good chemical resistance, performance at high temperatures, low coefficient of friction and high strength they can be found in many demanding applications across a variety of industries such as Oil & Gas, Aerospace, Nuclear and Chemical.

High-performance plastics include: PTFE, PCTFE, PEEK, PFA, FEP, ETFE, ECTFE, PPS, PES…

With our specialised processing equipment and wide tooling range, we are able to convert high performance and melt Fluoropolymer materials into semi-finished shapes for post machining or low to high volume of moulded components. With over 50 years of experience in the manufacture of PTFE, our range of engineering plastics and stock shapes is one of the most extensive in the world.

To find out how we can support your projects contact info@fluorocarbon.co.uk